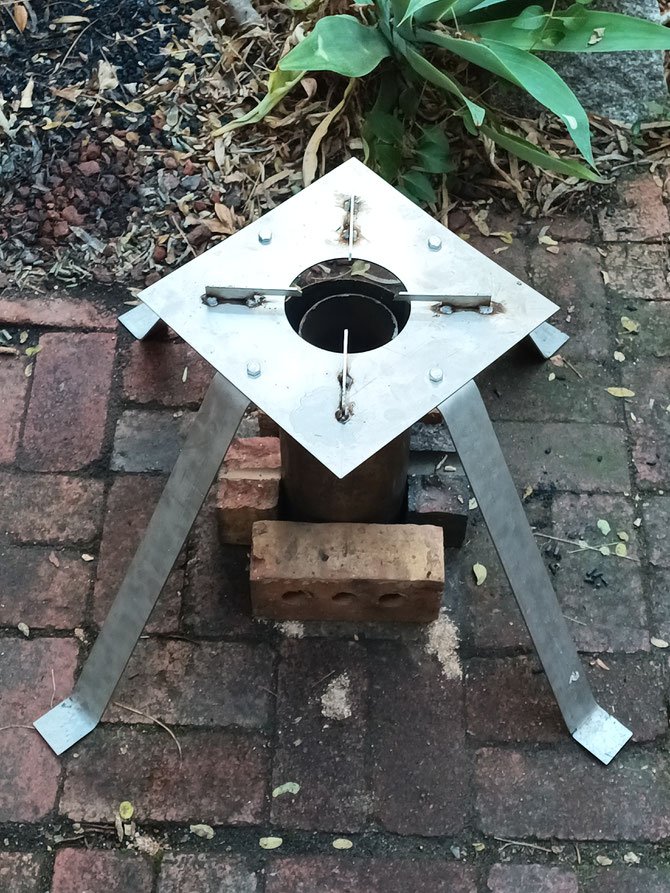

The 'Navigator Kitchen'

Why not build the C negative kitchen of your dreams? The Universal Pot Stand (UPS) is designed for ergonomics (you can sit on a chair while you cook), small or large manufacturing, bolt-on modularity, logistics (it can be packed down), durability (2.5mm 304 ss), suitability for most stainless cookware and is stove/burner agnostic eg. 'Navigator Burner' or as other stoves/burners evolve over the years, the UPS should stand the test of time.

I used 304 2.5mm stainless steel for the parts. The CAD can be viewed in 'LibreCAD' cross-platform software. Maybe you could form a TLUD Science-Art collective and pool resources, share parts and swap knowledge and skills?

'Navigator Burner'

No patents or patents pending. This 'Navigator Burner' design is an adaptation for a grinder and steel tube based on the Top-Lit UpDraft (TLUD) mainframe design principles which are completely 'Open source' to use.

Technical specifications

- Burner weight: 1.31kg (without heat and wind shield)

- Burner volume: 3 litres

- Wood pellets. Weight (max): 1.15kg

- Cost: 15kg bag wood pellets/1.15kg per burn (max) = 13 burns so at $19.95 per bag, $1.53 per burn

- Approximately the same fuel efficiency as the Navigator Stove 'Backup' TLUD stove (see 'Navigator Stove (NS)' page above) but with double the burn time

1st burn

- wood pellets

- ambient temperature: 15 degrees Celsius

- 5m startup

- 3L billy 2.8L water boiling time: 35m

- simmering for the rest of the burn

- burn time: 2h1m

- Biochar recovery: 100%

2nd burn

- ambient temperature: 11 degrees Celsius

- 5m startup

- 14L water in 15L stainless stockpot

- t=0, 10degsC

- t=30, 29

- t=60, 47

- t=90, 63

- t=120, 74

- t=129, 72

- burn time: 2h9m

- Biochar recovery: 100%

Meets the 'safe zone' for safe water sterilisation (see research paper below)

I take no responsibility for stability issues with this design though it does seem to be stable on a flat surface with the bottom of the tube squared off at 90 degrees. The stabilised heat and wind shield tube should work well for unprotected/exposed outdoor use of the burner and UPS but needs to be tested.

I should mention too that the heat and wind shield and bricks (or rocks) will interfere with quench system using an oven tray/saucepan/pot. In this design, a soil 'quench' can be used to finish the burn which could be appropriate for some local conditions eg.water scarcity with available environmental soil.

Operation

-position the burner in the centre of a thick oven tray or thick bottomed saucepan on a flat surface

-fill the burner with fuel eg.wood pellets, rice husk pellets, bamboo, sticks etc. up to desired level to a maximum height of 10mm below the secondary air slots

-add a circle of firelighter gel 2cm in from the tube edge (or 3 cotton wool buds soaked in kerosene)

-position the UPS centrally above the burner

-light the burner from the top with a wooden skewer lit at one end (or a BBQ lighter)

-position the cooking accessory eg.15L stainless stockpot on top of the stove top after 5 minutes

-ready to run without adding any additional fuel during the burn

At the end of the burn:

-flame goes out and usually smoke follows

-put on some leather gardening gloves (and keep them on until the water quench or soil quench has been performed)

-remove the cooking accessory

1-Water quench (if enough water is available). Add water from above the top of the burner eg.water jug, for initial quench of biochar pellets until oven tray/saucepan/pot water level is above the primary air slots (mind the steam)

-remove the UPS holding 2 legs

-lift the burner vertically eg. 20cm above the oven tray/saucepan, with billy lifters/pliers/C clamp, and the biochar will fall out the bottom (may need to use a stick to push out the biochar)

-using a stick, stir the biochar into the water and there will then be a complete quench

-wait 10 minutes then, wearing leather gloves, empty the oven tray/saucepan/pot into a bucket eg. a 20L stainless one, then it will be ready for the next burn

OR

2-Soil 'quench'. Next to the burner, dig some soil and make a pile before the burn.

-remove the UPS holding 2 legs

-fill up the air space between the heat and wind shield and burner plus the air space inside the burner, above the biochar, with soil

-leave for 10 minutes

-lift the burner vertically with billy lifters/pliers/C clamp until all the biochar and soil has fallen out the bottom (may need to use a stick to push out the biochar and soil)

-mix the biochar in with the soil inside the shield space

-lift the shield with billy lifters/pliers/C clamp and remove it

-add the biochar and soil mix back into the soil hole, next to the burner - the climate and microbes will love it!)

END

Conclusions

Maybe the 'Navigator Burner' (with optional heat and wind shield tube for exposed outdoor use) and UPS could be the best option as an outdoor institutional cooking and sanitation system and kitchen. The initial results above look very promising.

The UPS can be fabricated using local fabricators if available with a good skillset however both welding gear and a press brake are needed for the UPS. The 'Navigator Burner' can be fabricated with a basic grinder skillset.

It's a bit cocky to say this, but I believe now that Natural gas ('Unnatural methane' - yes folks, it's 'Ancient Sunlight' as opposed to practically unlimited 'New Sunlight' for biomass feedstock) is obsolete and shouldn't be mined, when the above 'Carbon negative' alternative works very well.

Maybe one day we'll have a 'Fossil Free' Civilisation but it's a very long journey to get there.

If all of this is too hard or costly or no access to tools, materials, skills, fabricators etc., then there's also the 'Fabstove' approved by Dr TLUD - but, at this stage is only available in South Africa and the U.S.A. and is going to cost you some clam shells.

http://www.ekasi.energy/

It's worth checking out the video here:

https://blueskybiochar.com/products/fabstove-tlud-clean-cook-stove-coming-soon

Learn by building. You won't regret it!:)

Permachar

Permachar